When excavating a pit deeper than 2 m, retaining wall is required.

The installation of a pile sheet in a pit enables excavation to a depth of 10 - 20 m. The area with surrounding buildings affected by the pit excavation is 4 times the depth of the pit. Pit excavation near an existing building without installing a sheet pile can lead to dramatic deformations and even can cause the collapse of the building.

There are the following types of retaining structures:

A certain type of retaining structures should be selected depending on such factor as the presence of groundwater, soil type and the pit depth. Below, each type of retaining wall is discussed in more detail.

The installation of a pile sheet in a pit enables excavation to a depth of 10 - 20 m. The area with surrounding buildings affected by the pit excavation is 4 times the depth of the pit. Pit excavation near an existing building without installing a sheet pile can lead to dramatic deformations and even can cause the collapse of the building.

There are the following types of retaining structures:

- pipe sheet piles

- Larssen sheet piles

- bored piles

- jet piles

- diaphragm (trench) wall

A certain type of retaining structures should be selected depending on such factor as the presence of groundwater, soil type and the pit depth. Below, each type of retaining wall is discussed in more detail.

◤ _Description

RETAINING WALLS

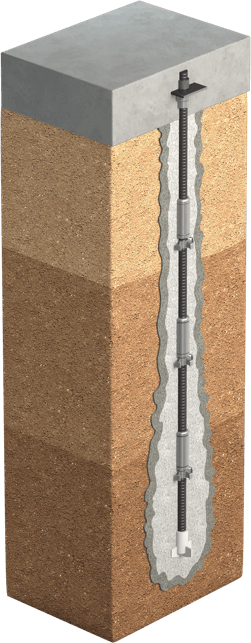

Steel pipe sheet pile is the cheapest type of retaining wall. It is used when excavating a pit in dry soils, i.e. when groundwater occurs below the pit bottom. Usually, second hand pipes are used as sheet pile in order to keep the cost of the latter to a minimum.

The technology is simple: a borehole is pre-drilled in the ground with an auger, then a pipe is inserted into the hole and filled with either soil or grout. It is always a better option to fill the sheet pile's annular space below the pit bottom with cement grout, since it helps securely fix the pipe downhole and prevent further displacements of the retaining all.

As a rule, pipes with a diameter of 325 - 530 mm are used in steel pipe sheet piles. The spacing of the pipes in the sheet pile is subject to calculation and usually ranges from 1.0 to 1.5 m. In order to prevent soil pattering between the pipes, timber lagging is provided.

The sheet pile length is derived from geotechnical calculations in software (Plaxis, GeoWall, Geo 5 Sheeting Design). Tentatively, the length of the sheet pile can be taken 1.5 to 2 times the depth of the pit.

The main advantage of the pipe sheet pile is its low cost, while the main shortcoming is that it cannot be used in wet soils.

Normally, pipe sheet piles find application in stable clay soils. If a pit sheet pile needs to be installed in soils saturated with water, as a rule, jet piles or Larssen sheet piles are the preferred option. These two technologies are comparable cost-wise.

The technology is simple: a borehole is pre-drilled in the ground with an auger, then a pipe is inserted into the hole and filled with either soil or grout. It is always a better option to fill the sheet pile's annular space below the pit bottom with cement grout, since it helps securely fix the pipe downhole and prevent further displacements of the retaining all.

As a rule, pipes with a diameter of 325 - 530 mm are used in steel pipe sheet piles. The spacing of the pipes in the sheet pile is subject to calculation and usually ranges from 1.0 to 1.5 m. In order to prevent soil pattering between the pipes, timber lagging is provided.

The sheet pile length is derived from geotechnical calculations in software (Plaxis, GeoWall, Geo 5 Sheeting Design). Tentatively, the length of the sheet pile can be taken 1.5 to 2 times the depth of the pit.

The main advantage of the pipe sheet pile is its low cost, while the main shortcoming is that it cannot be used in wet soils.

Normally, pipe sheet piles find application in stable clay soils. If a pit sheet pile needs to be installed in soils saturated with water, as a rule, jet piles or Larssen sheet piles are the preferred option. These two technologies are comparable cost-wise.

◤ _technologies

Steel pipe sheet pile

The Larssen sheet pile is a steel profile with a U, Z or S-shape cross-section. The interlock connection prevents water from coming to the pit. This type of sheet pile is designed specifically for retaining walls. The sheet piles are interconnected by means of special interlocks (grooves).

Sheet pile driving can be performed by several methods:

The main advantage of a steel sheet pile is that it can be reused. It is removed after the pit filling is completed and used in other projects. In some instances, however, it may be impossible to remove some or all sheet piles. Usually, one sheet pile can be reused 2 or 3 times. After that, it is no longer fit for use. Used sheet piles are available for rent, so there is no need to buy them.

The second advantage of the Larssen sheet pile is the possibility to install it from the water or into the water. It is common practice to use Larssen sheet piles in the construction of piers and embankments or when building bridge supports in the riverbed and water bodies.

The less stable the soil, the easier it is to drive the sheet pile. In stable soils, pre-drilled borehole may be required to facilitate the installation of a sheet pile. This, however, pushes the cost of pile sheet installation up.

The limitation posed by Larssen sheet piles is that it cannot be driven into fill soils with the inclusion of construction debris, as well as in gravelly and semi-rocky soils.

Nowadays, such sheet pile grades as Arcelor and Vitkovice are widely presented on the market. These vendors offer a wide range of sheet piles for different pits.

Sheet pile driving can be performed by several methods:

- vibratory sheet pile driving

- sheet pile jacking

The main advantage of a steel sheet pile is that it can be reused. It is removed after the pit filling is completed and used in other projects. In some instances, however, it may be impossible to remove some or all sheet piles. Usually, one sheet pile can be reused 2 or 3 times. After that, it is no longer fit for use. Used sheet piles are available for rent, so there is no need to buy them.

The second advantage of the Larssen sheet pile is the possibility to install it from the water or into the water. It is common practice to use Larssen sheet piles in the construction of piers and embankments or when building bridge supports in the riverbed and water bodies.

The less stable the soil, the easier it is to drive the sheet pile. In stable soils, pre-drilled borehole may be required to facilitate the installation of a sheet pile. This, however, pushes the cost of pile sheet installation up.

The limitation posed by Larssen sheet piles is that it cannot be driven into fill soils with the inclusion of construction debris, as well as in gravelly and semi-rocky soils.

Nowadays, such sheet pile grades as Arcelor and Vitkovice are widely presented on the market. These vendors offer a wide range of sheet piles for different pits.

Larssen sheet piles

The jet grouting technology can be used to make retaining structure in wet soils. After installing soil-cement piles, a pipe with a diameter of 159–219 mm is run in into them. This must be done immediately until the cement grout has gained strength. For jet piles with a diameter of 600 - 800 mm, the spacing between them in the retaining structure is usually 500 mm.

The maximum length of jet piles that can be reinforced with a pipe in such manner is 20 m. In case of great depths, pipe running into the jet pile may be challenging.

In some cases, an I-beam can be used to reinforce the jet pile. This, however, requires the use of a vibro-driver. It is worth noting that for pipes with a diameter exceeding 219 mm, a vibro-driver is also needed.

The advantages of retaining structures made of jet piles include:

The disadvantage is the poor performance of the soil-cement in clay soils. For such soils, a sheet pile made of pipes or bored piles will be a more suitable option.

A combination of bored piles and Jet piles is acceptable in a retaining structure. All lateral loads from the soil are taken by the bored piles, while the jet piles are positioned between the bored piles and function as a cut-off curtain.

The maximum length of jet piles that can be reinforced with a pipe in such manner is 20 m. In case of great depths, pipe running into the jet pile may be challenging.

In some cases, an I-beam can be used to reinforce the jet pile. This, however, requires the use of a vibro-driver. It is worth noting that for pipes with a diameter exceeding 219 mm, a vibro-driver is also needed.

The advantages of retaining structures made of jet piles include:

- High performance rate (up to 200 running meters per day).

- A pit can be excavated in soils with ground water.

- Pit construction can be performed in confined spaces, including inside the building when deepening the basement floor.

- Retaining structure can be installed in gravel soils.

The disadvantage is the poor performance of the soil-cement in clay soils. For such soils, a sheet pile made of pipes or bored piles will be a more suitable option.

A combination of bored piles and Jet piles is acceptable in a retaining structure. All lateral loads from the soil are taken by the bored piles, while the jet piles are positioned between the bored piles and function as a cut-off curtain.

Jet piles

When installing cast-in-place piles in wet soils, a casing pipe is used for drilling, and the borehole is concreted by means of a tremie pipe as it is pulled out. As the final operation, the reinforcing cage is run in downhole.

In the construction of retaining structures, as a rule, secant piles with a diameter of 600 - 1,000 mm are used. Pits can be excavated to the depth of up to 15 - 20 m due to sufficiently high strength and stiffness of bored piles.

Retaining wall made of bored piles is more expensive than that made of jet piles, and construction takes longer time as well.

A noteworthy solution for unstable watered soils is a retaining wall made of cast-in-place piles with plug constructed of jet piles. In this case, the bored piles bear the main load, while the plug made of jet elements reduces the amount of water coming into the pit.

In the construction of retaining structures, as a rule, secant piles with a diameter of 600 - 1,000 mm are used. Pits can be excavated to the depth of up to 15 - 20 m due to sufficiently high strength and stiffness of bored piles.

Retaining wall made of bored piles is more expensive than that made of jet piles, and construction takes longer time as well.

A noteworthy solution for unstable watered soils is a retaining wall made of cast-in-place piles with plug constructed of jet piles. In this case, the bored piles bear the main load, while the plug made of jet elements reduces the amount of water coming into the pit.

Bored secant piles

A diaphragm wall is the most reliable enclosing structure, having the maximum ultimate bending moment and enabling the construction of extremely deep pits. At the same time, however, the diaphragm wall is the most expensive method for retaining structure construction.

The construction of a diaphragm wall as a retaining structure solution consists in digging deep narrow trenches under the protection of clay grout and then concreting with the use of a vertically moving pipe. Trenches are excavated zone by zone. The horizontal length of such zones corresponds to the size of attachments, usually within a range from 2,500 to 6,800 mm.

In addition, when installing a diaphragm wall in man-made porous soils or in fractured limestones, the loss of bentonite mud may be observed. To prevent this, soil pre-grouting is necessary, further increasing the cost, which is already high.

The construction of a diaphragm wall as a retaining structure solution consists in digging deep narrow trenches under the protection of clay grout and then concreting with the use of a vertically moving pipe. Trenches are excavated zone by zone. The horizontal length of such zones corresponds to the size of attachments, usually within a range from 2,500 to 6,800 mm.

In addition, when installing a diaphragm wall in man-made porous soils or in fractured limestones, the loss of bentonite mud may be observed. To prevent this, soil pre-grouting is necessary, further increasing the cost, which is already high.

Diaphragm (trench) wall

To minimize horizontal displacements and excavate deep pits, sheet piles must be secured with anchoring systems (ground anchors) or strutting systems (struts) made of pipes.

A ground anchor is an inclined pile, which prevents horizontal movement of retaining walls or a pit. They are usually installed to fix retaining structures, retaining walls and slopes.

If compared with piping struts, ground anchors allow quick soil excavation from the pit and erecting a cast-in-place building without using temporary supports and dismantling the struts. All this helps reduce the overall work duration.

Today, there are two major technologies to install ground anchors:

Let's take a closer look at the ground anchorage technology.

A ground anchor is an inclined pile, which prevents horizontal movement of retaining walls or a pit. They are usually installed to fix retaining structures, retaining walls and slopes.

If compared with piping struts, ground anchors allow quick soil excavation from the pit and erecting a cast-in-place building without using temporary supports and dismantling the struts. All this helps reduce the overall work duration.

Today, there are two major technologies to install ground anchors:

- ground anchors with threaded rods TITAN

- ground strand anchors

Let's take a closer look at the ground anchorage technology.

◤ _Description

GROUND ANCHORS

A ground anchor with a Titan threaded rod is installed within a single stage, where drilling, reinforcement and grouting (formation of the root) occur simultaneously. When drilling is completed, the tubular threaded rod is left in the ground anchor as a reinforcing element.

Drilling is performed with tubular threaded rods. Due to their knurled screw-like surface, the rods show excellent adhesion to the anchor root.

Threaded rods may be 1, 2 and 3 meter long. The rods are connected to each other by couplings. Thus, the ground anchors may have any length. Anchor rods can withstand a load in the range from 50 to 260 tons.

Many opt for Titan ground anchors because of their high-performance rate, which is 1.5 - 2 times superior to that of strand anchors.

The disadvantage is the higher cost per 1 running meter of the rod compared with a strand anchor rod.

To be fair, however, it should be mentioned that the price of 1 meter of a Titan ground anchor, including the cost of work and materials, is comparable to the price of a ground strand anchor.

Anchor piles are sometimes used to prevent the uplift of underground tanks or parking lots in watered soils.

Drilling is performed with tubular threaded rods. Due to their knurled screw-like surface, the rods show excellent adhesion to the anchor root.

Threaded rods may be 1, 2 and 3 meter long. The rods are connected to each other by couplings. Thus, the ground anchors may have any length. Anchor rods can withstand a load in the range from 50 to 260 tons.

Many opt for Titan ground anchors because of their high-performance rate, which is 1.5 - 2 times superior to that of strand anchors.

The disadvantage is the higher cost per 1 running meter of the rod compared with a strand anchor rod.

To be fair, however, it should be mentioned that the price of 1 meter of a Titan ground anchor, including the cost of work and materials, is comparable to the price of a ground strand anchor.

Anchor piles are sometimes used to prevent the uplift of underground tanks or parking lots in watered soils.

◤ _technologies

TITAN bar ground anchors

Ground anchors made using the jet grouting technology are called MiniJet anchors. Since a jet of grout erodes the anchor's root, ground anchors have a diameter ranging from 250 to 400 mm. In this case, the required bearing capacity can be obtained with a shorter anchor length, so total length of the ground anchors may be reduced.

Advantages of Titan and MiniJet anchors:

Advantages of Titan and MiniJet anchors:

- high performance rate (up to 300 running meters of anchors per day)

- suitable for use in watered soils

- anchors can be attached to the diaphragm wall with plates, without a capping beam

- ground anchors can be installed in confined spaces

- high specific ground bearing capacity of the anchor

MiniJet ground anchors

Grouted ground anchors are a classic time-tested technology. At the first stage, pre-drilling of a borehole is performed with flights augers or using casing pipes for protection. Then an anchor strand is run in the borehole. Then the borehole is filled with cement grout through a grouting pipe. At the final stage, cement grout is grouted to the anchor under pressure through another pipe a day later.

The anchor rod consists of several strands (steel seven-wire ropes). The number of strands is selected depending on the load on the ground anchor. Each strand can withstand a force of about 20-22 tons. Usually, anchors have from 3 to 7 strands, which enables them to withstand a load of 60 - 150 tons.

The classic ground anchor consists of two parts: the free length and the root. Along the free length, each strand of the anchor is isolated from the cement body and enclosed in a plastic pipe. In the anchor's root, special bell-outs are provided for good adhesion of the strand to cement. Due to this system, the load is transferred directly to the anchor's root, without affecting the risky sliding of the pit.

Advantages of Titan and MiniJet anchors:

The main disadvantage of strand anchors is low performance rate, since greater labor inputs are required for the installation and run-in of the anchor rod into the borehole.

The anchor rod consists of several strands (steel seven-wire ropes). The number of strands is selected depending on the load on the ground anchor. Each strand can withstand a force of about 20-22 tons. Usually, anchors have from 3 to 7 strands, which enables them to withstand a load of 60 - 150 tons.

The classic ground anchor consists of two parts: the free length and the root. Along the free length, each strand of the anchor is isolated from the cement body and enclosed in a plastic pipe. In the anchor's root, special bell-outs are provided for good adhesion of the strand to cement. Due to this system, the load is transferred directly to the anchor's root, without affecting the risky sliding of the pit.

Advantages of Titan and MiniJet anchors:

- They have the classic free length, preventing the impact on the sliding of the pit

- Double protection for permanent ground anchors can be provided. In this case, the strand anchor is also enclosed in a plastic corrugated pipe

- Anchors' length need not be necessarily a multiple of a meter, so anchors may have any length. For instance, ground anchors may be 14.2 m or 17.1 m long. There is no need to round up the values to 15 m or 18 m

- Lower cost of the anchor rod

The main disadvantage of strand anchors is low performance rate, since greater labor inputs are required for the installation and run-in of the anchor rod into the borehole.

Strand ground anchors

As prescribed by regulations, all ground anchors are subject to a load test when a load 1.25 times the design load is applied to the anchor. 10% of all ground anchors are tested using a load 1.5 times the design one. The prestressed load is obtained by calculations and is usually 30%–50% of the design load.

◤ _quality & cost

Ground anchor quality control

The price, first of all, depends on the load on the anchor. As a rule, the deeper the pit, the higher the design load on the ground anchor, consequently, a stronger anchor rod must be used, which escalates the price.

The anchor's cost also depends on the soil characteristics. In less stable soils, the drilling process is easier, so the price will be lower.

The anchor's cost also depends on the soil characteristics. In less stable soils, the drilling process is easier, so the price will be lower.

The cost of the ground anchor

We are ready to make the analysis and design of the retaining structure using any technology, including anchoring.

Analyses are performed in the software such as GeoWall, Plaxis, Sheeting Design (Geo 5).

Thanks to in-depth understanding of all the pros and cons of each technology, our team will perform the pit analysis, pick the optimal retaining wall option, and develop the retaining structure design. We also perform assessments of the pit excavation impact on the surrounding buildings.

We are ready to make an initial calculation of the first section of the retaining structure for free.

Feel free to contact us!

Analyses are performed in the software such as GeoWall, Plaxis, Sheeting Design (Geo 5).

Thanks to in-depth understanding of all the pros and cons of each technology, our team will perform the pit analysis, pick the optimal retaining wall option, and develop the retaining structure design. We also perform assessments of the pit excavation impact on the surrounding buildings.

We are ready to make an initial calculation of the first section of the retaining structure for free.

Feel free to contact us!

We pick the most suitable technology for each task

Reference projects

▸

▸

▸

▸