◤ _Description

- grouting (injection) – soil cementation by injection

- vibro methods (flotations and compactions) – methods for soil compaction by vibration

- soil mixing

- jet grouting

A particular soil improvement method is selected in each case depending on the objective, the load, and the required settlement. Here's a brief description of each technology.

Nowadays, there is a number of soil improvement methods designed to improve the subgrade bearing capacity and reduce settlement, such as

Soil cementation is one of the cheapest soil improvement methods. It is usually used to fill voids and pores when stabilizing the subgrade soils of the foundations of existing buildings.

Soil cementation (grouting) technology

Soil cementation (grouting) technology

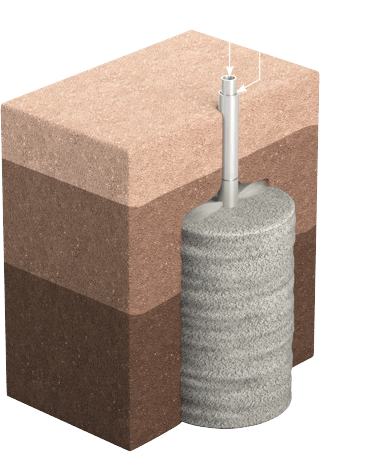

Grout injection lances with holes along their entire length are run into pre-drilled boreholes. Further, cement grout (cement mixed with water) is injected through these lances at a low pressure ranging from 2 to 5 bar.

Cementation can be used to improve sandy, gravelly, and fill soils.

Usually, cementation helps increase soil bearing capacity by 10–15%.

However, this technology poses difficulties for quality control activities.

Soil cementation (grouting) technology

Soil cementation (grouting) technology

Grout injection lances with holes along their entire length are run into pre-drilled boreholes. Further, cement grout (cement mixed with water) is injected through these lances at a low pressure ranging from 2 to 5 bar.

Cementation can be used to improve sandy, gravelly, and fill soils.

Usually, cementation helps increase soil bearing capacity by 10–15%.

However, this technology poses difficulties for quality control activities.

◤ _metods

Grouting (soil cementation)

Soil vibro compaction is done using a downhole vibrator. This method is designed for the improvement of loose sandy soils or fill soils up to a depth of 10 m. Compaction increases soil density, which leads to improved deformation behavior of soils. The most renowned project in which this method was used is the artificial islands in the Arab Emirates (The Palm Jumeirah).

Vibro compaction technology

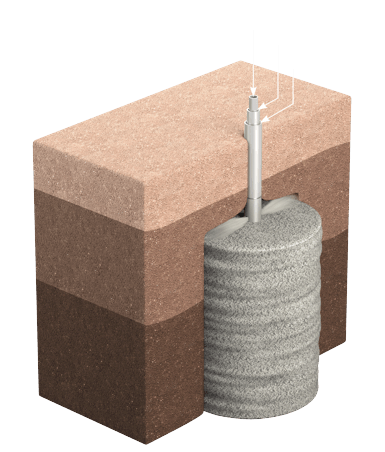

The working principle of vibro compaction assumes increasing the soil density by exposure to vibration, which is generated by a vibrator immersed right in the soil.

In addition to vibrations, water is supplied through the nozzles in the course of work. As a result, the soil particles begin to form a denser subgrade with a significant increase in the bearing capacity.

Sand is fed into the upper hopper of the vibrator. The vibrator and the hopper move along the guide mast of the tracked vehicle. The sand coming from under the vibrator is further compacted and pushed laterally. In the course of the vibrator's operation, compacted soil columns are formed, which take up loads together with the soil.

Compaction is most efficient in loose soils with high porosity. Clay soils cannot be compacted. To improve their load-bearing capacity, the vibro replacement method is used. This involves the creation of ground pillars (columns) made of crushed stone or sand and stone aggregate using a downhole vibrator.

In the vibro replacement technology, stone columns are often used to improve the load bearing properties of soft subgrade soils of roads and embankments.

Vibroflotation is most efficient in loose and fill soils.

Vibro compaction technology

The working principle of vibro compaction assumes increasing the soil density by exposure to vibration, which is generated by a vibrator immersed right in the soil.

In addition to vibrations, water is supplied through the nozzles in the course of work. As a result, the soil particles begin to form a denser subgrade with a significant increase in the bearing capacity.

Sand is fed into the upper hopper of the vibrator. The vibrator and the hopper move along the guide mast of the tracked vehicle. The sand coming from under the vibrator is further compacted and pushed laterally. In the course of the vibrator's operation, compacted soil columns are formed, which take up loads together with the soil.

Compaction is most efficient in loose soils with high porosity. Clay soils cannot be compacted. To improve their load-bearing capacity, the vibro replacement method is used. This involves the creation of ground pillars (columns) made of crushed stone or sand and stone aggregate using a downhole vibrator.

In the vibro replacement technology, stone columns are often used to improve the load bearing properties of soft subgrade soils of roads and embankments.

Vibroflotation is most efficient in loose and fill soils.

Vibro compaction

In grass-roots construction projects, soil cement elements (piles) are usually installed in a loose subgrade at pre-calculated intervals. Generally, this reduces the subgrade deformation capacity, while increasing its bearing capacity.

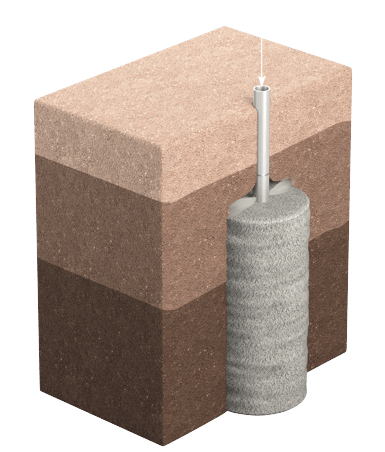

Deep soil mixing involves mechanical blending of in-situ soils with cement grout using blades on the tip of the drilling tool.

Cement grout is supplied through hollow rods to the holes on the tip of the drill string. Rotary drilling and cement grout injection occur simultaneously. The jet grout column diameter is determined by the size of the blades and ranges from 500 to 800 mm.

The method offers the following advantages:

The shortcomings include a lower production rate and significant inhomogeneity of the soil-cement composition.

The Soil Mixing technology is well suited for improving loose road subgrade soils.

Deep soil mixing involves mechanical blending of in-situ soils with cement grout using blades on the tip of the drilling tool.

Cement grout is supplied through hollow rods to the holes on the tip of the drill string. Rotary drilling and cement grout injection occur simultaneously. The jet grout column diameter is determined by the size of the blades and ranges from 500 to 800 mm.

The method offers the following advantages:

- pre-determined diameter of jet grout columns

- minimum amount of drilling sludge

The shortcomings include a lower production rate and significant inhomogeneity of the soil-cement composition.

The Soil Mixing technology is well suited for improving loose road subgrade soils.

Soil mixing

Jet grouting is the soil improvement technique which involves rotation of a cement grout jet under high pressure (up to 450 bar).

As the grout hardens, a new material – soil-cement (soil-concrete) – is formed, which has high strength and deformation characteristics.

If compared to conventional injection-based soil improvement methods, jet grouting enables stabilization of almost all kinds of soils – from wet sands to soft clays and silts.

The advantages of the jet grouting technology are:

Scope of the jet grouting technology application:

The jet piles are installed in two stages:

Soil-cement properties

The compressive strength of the soil-cement in sandy soils ranges from 3 to 10 MPa, and in clay soils – from 1 to 3 MPa. The Jet deformation modulus varies from 100 to 5,000 MPa in different types of soil.

Single fluid technology (Jet 1)

A cement grout jet is used to destroy the soil. The diameter of jet piles ranges from 500 to 600 mm in clay soils and from 700 to 900 mm in sandy soils. Jet 1 technology is the most widely used, predictable and high-performance method. It enables quite an accurate forecast of the jet pile diameter at the design stage.

Dual fluid technology (Jet 2)

In this scenario, compressed air energy is used to increase the diameter of the jet column. Double hollow rods are used to separately feed cement grout and compressed air to the jet monitor. Cement grout is supplied through the inner rods, while the outer ones deliver compressed air.

Piles produced using this technology may be from 1,200 to 500 mm in diameter, and in sands – 1,500 - 2,000 mm.

Today, after the Jet 2 technology morphed into a state-of-the-art SuperJet method, columns with a diameter of 3,000 - 5,000 mm can be created!

Triple fluid technology (Jet 3)

This option differs from those mentioned earlier in that the water-air jet is used exclusively to erode the soil and leave cavities in it, which are subsequently filled with cement grout. The Jet 3 technology requires the use of triple rods, therefore, it is not widely applied these days. In order to fully replace loose soil, it is first washed out by water using Jet 2 technology.

As the grout hardens, a new material – soil-cement (soil-concrete) – is formed, which has high strength and deformation characteristics.

If compared to conventional injection-based soil improvement methods, jet grouting enables stabilization of almost all kinds of soils – from wet sands to soft clays and silts.

The advantages of the jet grouting technology are:

- The results of soil improvement by jet grouting are predictable.

- High performance rate (up to 200 running meters of jet piles per day).

- It is suited for working in confined spaces (in basements, near existing buildings, on slopes).

- Piles can be installed under existing foundations (piles with a diameter of 300–900 mm can be installed through a hole, which is 100 mm in diameter).

- The methods help stabilize soft clay and wet soils.

Scope of the jet grouting technology application:

- strengthening of loose subgrade soils under buildings, roads, bridges or tunnels;

- foundation strengthening in the course of reconstruction or when adding extra floors;

- pit sheeting and retaining walls;

- installation of vertical and horizontal cut-off curtains to prevent water from coming to the pit.

The jet piles are installed in two stages:

- a borehole is pre-drilled up to the grade level (straight motion);

- during the reverse motion, cement grout is fed under high pressure (400–450 atm) through the nozzles on the lower tip of the drilling tool and the drill string is being pulled-out while rotating simultaneously.

Soil-cement properties

The compressive strength of the soil-cement in sandy soils ranges from 3 to 10 MPa, and in clay soils – from 1 to 3 MPa. The Jet deformation modulus varies from 100 to 5,000 MPa in different types of soil.

Single fluid technology (Jet 1)

A cement grout jet is used to destroy the soil. The diameter of jet piles ranges from 500 to 600 mm in clay soils and from 700 to 900 mm in sandy soils. Jet 1 technology is the most widely used, predictable and high-performance method. It enables quite an accurate forecast of the jet pile diameter at the design stage.

Dual fluid technology (Jet 2)

In this scenario, compressed air energy is used to increase the diameter of the jet column. Double hollow rods are used to separately feed cement grout and compressed air to the jet monitor. Cement grout is supplied through the inner rods, while the outer ones deliver compressed air.

Piles produced using this technology may be from 1,200 to 500 mm in diameter, and in sands – 1,500 - 2,000 mm.

Today, after the Jet 2 technology morphed into a state-of-the-art SuperJet method, columns with a diameter of 3,000 - 5,000 mm can be created!

Triple fluid technology (Jet 3)

This option differs from those mentioned earlier in that the water-air jet is used exclusively to erode the soil and leave cavities in it, which are subsequently filled with cement grout. The Jet 3 technology requires the use of triple rods, therefore, it is not widely applied these days. In order to fully replace loose soil, it is first washed out by water using Jet 2 technology.

Jet grouting

Triple fluid technology

(Jet 3)

(Jet 3)

Single fluid technology

(Jet 1)

(Jet 1)

Dual fluid technology

(Jet 2)

(Jet 2)

Сement mortar

Сement mortar

Air

Сement mortar

Air

Water

We perform the required strength and settlement analysis, calculate the necessary soil stabilization depth, and identify the scope of work.

The cost of the soil improvement works is affected by many factors. For example, when performing work in confined spaces inside buildings, the cost of using jet piles will be higher than in the projects that use a large high-performance drilling machine.

The cost also depends heavily on the cement consumption. The more cement is consumed, the higher the cost of soil improvement works.

Our company has vast experience in developing soil improvement designs.

We are ready to develop a draft technical proposal for soil stabilization in one section at your request, free of charge.

Feel free to contact us!

The cost of the soil improvement works is affected by many factors. For example, when performing work in confined spaces inside buildings, the cost of using jet piles will be higher than in the projects that use a large high-performance drilling machine.

The cost also depends heavily on the cement consumption. The more cement is consumed, the higher the cost of soil improvement works.

Our company has vast experience in developing soil improvement designs.

We are ready to develop a draft technical proposal for soil stabilization in one section at your request, free of charge.

Feel free to contact us!

We pick the most suitable technology for each task

Reference projects

▸

▸

▸

▸