Stopite V Stik

ODGOVORILI BOMO NA VSA VAŠA VPRAŠANJA, NAREDILI IZRAČUNE IN STROKOVNO SVETOVALI

- loads on existing building foundations increased when adding extra floors

- subgrade soil characteristics deteriorated during the use of the building

- errors in the foundation design or construction

If the load for an existing building is increased or a pit is excavated near the building, foundations must be strengthened using micro piles.

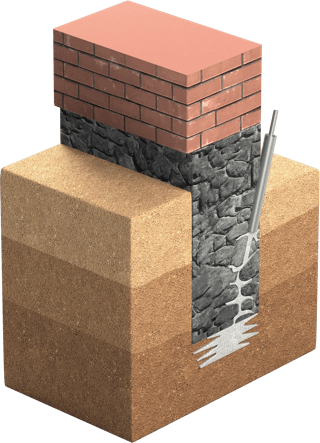

Cementation is a low-cost method of foundation strengthening, suitable when potential voids in the foundation and under it need to be filled.

It is worth noting that cementation improves bearing capacity of foundations and soils by about 10-20%.

◤ _Description

Foundation strengthening may be required in the following cases:

◤ metods

Foundation strengthening is usually done using the following methods:

Usually, this measure is taken to restore the foundation bearing capacity and fill possible voids at the foundation-soil interface.

Cement grout is injected under pressure (2-5 bar) through the boreholes drilled. This helps eliminate voids in the foundation and at the foundation-soil interface.

Cement grout is injected under pressure (2-5 bar) through the boreholes drilled. This helps eliminate voids in the foundation and at the foundation-soil interface.

Grouting of the foundation

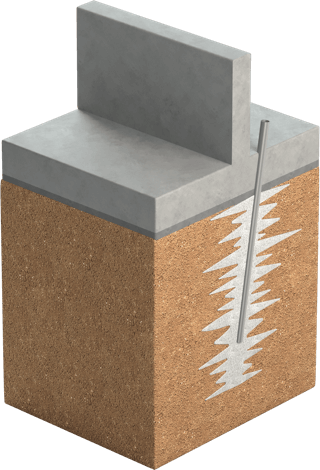

The improvement of subgrade strength and deformation characteristics up to a depth of more than 1.0 m under the foundation bed is done using injection pipes.

Cement grout is pumped into injection pipes positioned at the distance of 1.0 m from each other. The pipes are run-in into one hole and injection is performed in sequence, one by one. Normally, the grouting depth ranges from 2.0 to 5.0 m.

Cement grout is pumped into injection pipes positioned at the distance of 1.0 m from each other. The pipes are run-in into one hole and injection is performed in sequence, one by one. Normally, the grouting depth ranges from 2.0 to 5.0 m.

Grouting using injection pipes

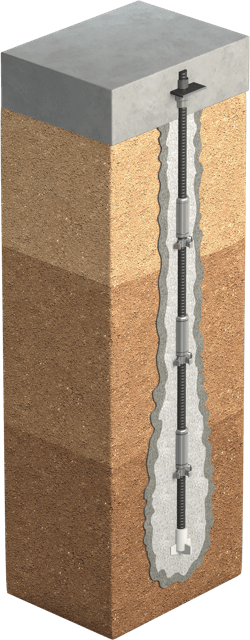

Micro piles are cast-in-situ bored piles with a diameter of up to 200 - 250 mm, which are produced by drilling a hole and injecting cement grout.

Underpinning with Micro piles

MICRO PILES CAN BE INSTALLED WITH THE USE OF DIFFERENT METHODS:

01. Strengthening foundation (underpining) using Jet or MiniJet piles

The jet grouting technology involves cement grout injection under high pressure with simultaneous rotation and lifting of the drilling tool. Eventually, a jet pile with a diameter of 300 - 800 mm is formed in the soil.

The advantage of the jet grouting technology for strengthening foundations consists in minimal foundation weakening, since drilling rods with a diameter of only 100 - 130 mm are used. Thus, the foundation rests securely on a pile with a diameter of 600 - 800 mm.

Once the pile is installed, the tube connected by the couplings can be run in immediately.

Small-size equipment enables the installation of jet piles within the perimeter of existing buildings when adding extra floors.

The MiniJet technology can be used to minimize the technological settlement of small individual foundations. Due to lower pressure used here, piles with a diameter of 300 – 400 mm can be formed. The MiniJet method assumes that drilling is performed with drill pipes on couplings, which then remain in the pile body as a reinforcing element.

02. Auger cast pile

This piling method is normally used to install new piles under existing buildings.

Drilling is performed with augers without adding water. Therefore, the technology is dry, and no drilling slurry is produced.

In stable soils, a borehole is drilled with augers at the first stage, and then tubes are run in, which are connected by couplings. At the final stage, the borehole is filled with cement grout. The pile diameter lies within the range of 150-200 mm that is by 20 mm larger than the augers' diameter. The diameter of the tube that can be immersed into the hole is 114-133 mm.

In case of wet soils, flights augers are used to feed cement grout during the reverse motion.

When auger drilling is used to strengthen existing foundations with micro piles, boreholes must be first drilled in the foundations with drilling machines having diamond bits with a diameter of 180-220 mm.

03. TITAN piles

The core of the Titan piling technology is the combination of drilling and cementation processes. The technology involves the use of special hollow drilling rods, which, after drilling, remain in the pile as a reinforcing element. The rods may be 1 m, 1.5 m, and 2 m long. They are connected together by couplings.

The major advantage of this method in comparison with auger cast piling is better productivity. The production rate of the Titan piling is 1.5 times the production rate of piles created with augers. The disadvantage is the higher price of 1 running meter of the threaded rod compared with a pipe or a reinforcement casing.

Small-size drilling rigs suitable for operating in confined spaces (from a building basement or on narrow streets) are used in the foundation strengthening works. The small-size drilling rig is only 600 mm wide and 2 m high.

The jet grouting technology involves cement grout injection under high pressure with simultaneous rotation and lifting of the drilling tool. Eventually, a jet pile with a diameter of 300 - 800 mm is formed in the soil.

The advantage of the jet grouting technology for strengthening foundations consists in minimal foundation weakening, since drilling rods with a diameter of only 100 - 130 mm are used. Thus, the foundation rests securely on a pile with a diameter of 600 - 800 mm.

Once the pile is installed, the tube connected by the couplings can be run in immediately.

Small-size equipment enables the installation of jet piles within the perimeter of existing buildings when adding extra floors.

The MiniJet technology can be used to minimize the technological settlement of small individual foundations. Due to lower pressure used here, piles with a diameter of 300 – 400 mm can be formed. The MiniJet method assumes that drilling is performed with drill pipes on couplings, which then remain in the pile body as a reinforcing element.

02. Auger cast pile

This piling method is normally used to install new piles under existing buildings.

Drilling is performed with augers without adding water. Therefore, the technology is dry, and no drilling slurry is produced.

In stable soils, a borehole is drilled with augers at the first stage, and then tubes are run in, which are connected by couplings. At the final stage, the borehole is filled with cement grout. The pile diameter lies within the range of 150-200 mm that is by 20 mm larger than the augers' diameter. The diameter of the tube that can be immersed into the hole is 114-133 mm.

In case of wet soils, flights augers are used to feed cement grout during the reverse motion.

When auger drilling is used to strengthen existing foundations with micro piles, boreholes must be first drilled in the foundations with drilling machines having diamond bits with a diameter of 180-220 mm.

03. TITAN piles

The core of the Titan piling technology is the combination of drilling and cementation processes. The technology involves the use of special hollow drilling rods, which, after drilling, remain in the pile as a reinforcing element. The rods may be 1 m, 1.5 m, and 2 m long. They are connected together by couplings.

The major advantage of this method in comparison with auger cast piling is better productivity. The production rate of the Titan piling is 1.5 times the production rate of piles created with augers. The disadvantage is the higher price of 1 running meter of the threaded rod compared with a pipe or a reinforcement casing.

Small-size drilling rigs suitable for operating in confined spaces (from a building basement or on narrow streets) are used in the foundation strengthening works. The small-size drilling rig is only 600 mm wide and 2 m high.

This grouting method involves injection of cement grout at certain vertical intervals through tube-à-manchette (perforated pipes with sleeves) pre-installed in the soil.

In order to inject grout into the desired interval, a dual packer is inserted into the pipe, which helps deliver the grout to the target zone. Once the design quantity of cement grout is injected, the packer is moved to a new interval and the operation is repeated. The grout injection interval along the tube length is 300 - 500 mm.

In order to inject grout into the desired interval, a dual packer is inserted into the pipe, which helps deliver the grout to the target zone. Once the design quantity of cement grout is injected, the packer is moved to a new interval and the operation is repeated. The grout injection interval along the tube length is 300 - 500 mm.

Tube-a-Manchettes (TAM), Sleeve pipes grouting

Our company has vast experience in developing foundation strengthening designs using piles and grouting. We select the most suitable method for every task, because we know all the pros and cons of each technology.

We are ready to develop a draft technical proposal for foundation strengthening in one section at your request, free of charge.

Feel free to contact us!

We are ready to develop a draft technical proposal for foundation strengthening in one section at your request, free of charge.

Feel free to contact us!

We pick the most suitable technology for each task

Reference projects

▸

▸

▸

▸